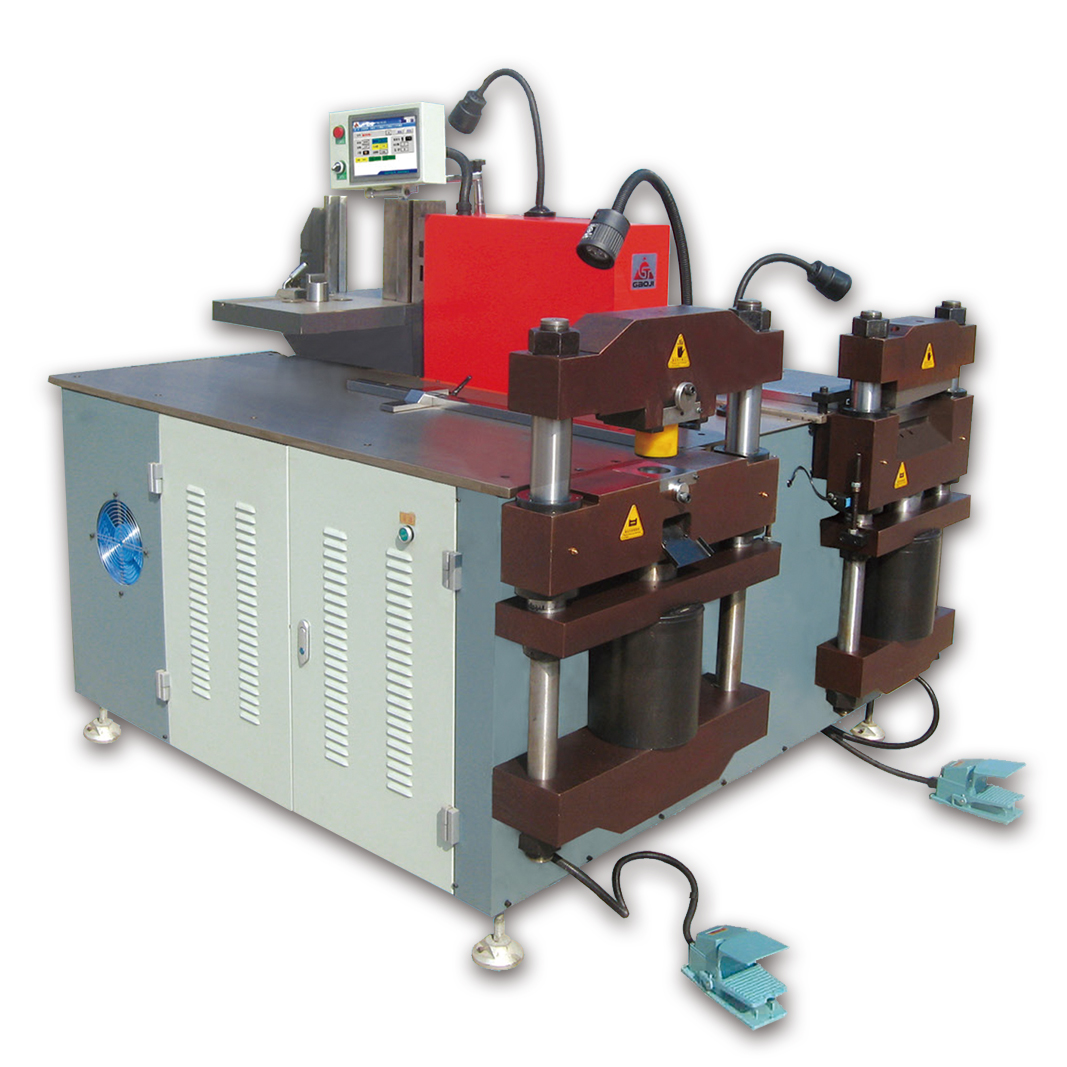

Busbar Punch Shear Bend machine

Basic Info

Model No.: BM603-S-3

Product Description

Main functions and features:

The Busbar Punch Shear Bend machine is the patented product developed by our company. Comparing with the traditional busbar processing machine, this product has the following advantages and features:

1. The punching unit adopts column structure, with novel and unique design rendering reasonable force bearing, and thus effectively guarantees the long-term use without deformation;

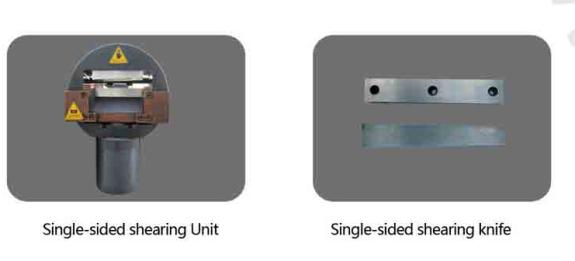

2. The shearing unit adopts round integral structure, with novel and unique design rendering reasonable force bearing, and thus effectively guarantees the long-term use without deformation;

3. The bending unit uses integral structure and CNC angle control mode, allowing easy operation and high accuracy;

4. This machine adopts the design approach of double-layer work bench, truly realizing the simultaneous working of three stations without mutual interference;

5. The machine is provided with an automatic oil charge and discharge system, easy to operate, with the hydraulic oil charged into the oil tank via a filter so as to protect the entire hydraulic system from contamination;

6. This machine is provided with stainless steel oil tank to protect the hydraulic oil from corrosive deterioration, and extend the service life of hydraulic oil and the seals;

7. Swappable dies offering extreme convenience;

8. PLC control that is stable and reliable.

Configuration of the machine Work Bench Dimension (mm) Machine Weight (kg) Number of Motors Total Motor Power (kw) Working Voltage (v) Number of Hydraulic Units (MPa) Control Mode Layer Ⅰ:1500*1200 1280 3+1 11.37 380 3*31.5 PLC+CNC angle bending Layer Ⅱ:840*370

Main technical parameters: Description Material Machining W*H (mm) Max Punched Hole Max Output Force (kn) Punching unit Copper/Aluminum 16*160 Ø32 600 Shearing unit Copper/Aluminum Punching and shearing:12*160

Simple shearing:15*160 350 Bending unit Copper/Aluminum Level bending:15*160

Vertical bending:12*120 350

Packing details

1) Applying Anti-Rust Oil

2) Covering with stretch film

3) Covering aluminum air bag

4) Vacuuming air bags

5) Boxing all the pallet

6) Loading to the container

Product Categories : Busbar Processing Machine